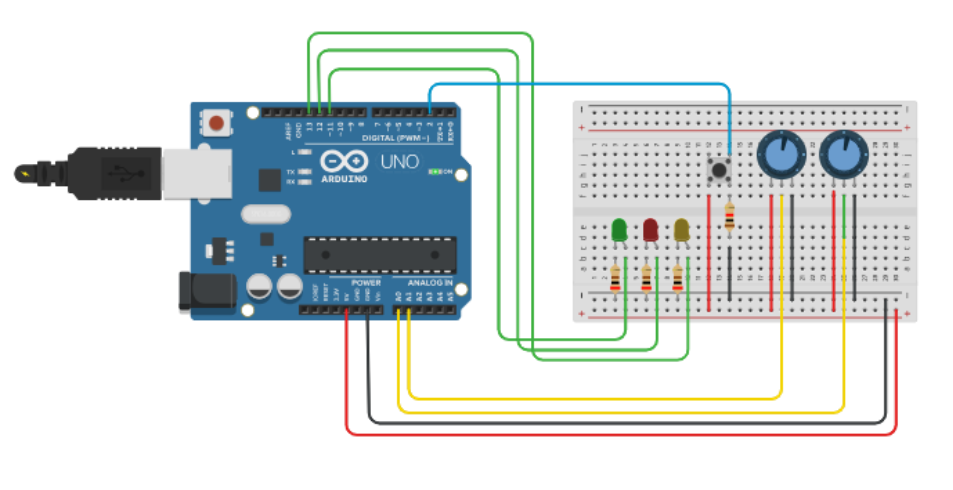

The Industrial Oven Temperature Control project using Arduino is designed to ensure precise and uniform temperature management within an industrial oven. This advanced system incorporates buttons, a potentiometer, and LEDs for indications, along with two temperature sensors placed strategically at the front and back of the oven. This setup allows for accurate monitoring and control of the oven’s internal environment, ensuring even heating and optimal performance.

Components used in Industrial Oven Project:

Arduino UNO: The Arduino acts as the central processing unit, managing inputs from the buttons, potentiometer, and two temperature sensors to control the oven’s heating elements.

Temperature Sensors: we will use the two temperature sensors in this Project, Front and Back sensor By using two sensors, the system can detect any temperature discrepancies between the front and back, ensuring even heat distribution throughout the oven.

Buttons: The system includes buttons for setting the desired temperature, selecting between different heating modes, and starting or stopping the oven. These buttons provide easy and direct control for the operator.

Potentiometer: The potentiometer allows for precise adjustment of the target temperature, giving the operator fine control over the heating process.

LED Indicators:

- Heating LED: Lights up when the oven is actively heating, indicating that the system is working to reach or maintain the set temperature.

- Target Reached LED: Illuminates when the oven reaches the set temperature uniformly across both sensors, signaling that the desired conditions have been achieved.

- Temperature Discrepancy LED: A dedicated LED that lights up if a significant temperature difference is detected between the front and back sensors, alerting the operator to potential issues with heat distribution.

- Error LED: Flashes if the system detects any malfunctions, such as sensor failure or overheating, providing an early warning to prevent damage.

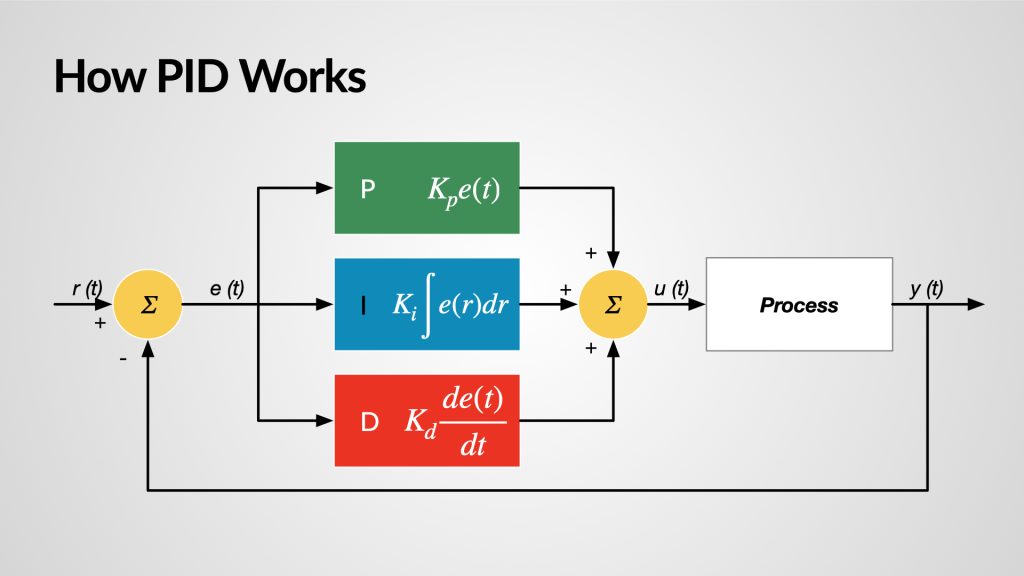

PID Control:

PID control, which stands for Proportional-Integral-Derivative control, is a widely used feedback control system in various industrial and engineering applications. It is designed to automatically adjust the output of a system to maintain a desired setpoint, even in the presence of disturbances or changes in the system.

Advantages of PID Control

- Simplicity: Despite being a powerful control method, PID is relatively easy to understand and implement.

- Flexibility: PID controllers can be tuned to work with many different types of systems and processes.

- Effectiveness: They provide precise and reliable control for systems with various dynamics and disturbances.

Circuit Diagram of Industrial Oven Project:

Code of Industrial Oven Project:

// initialization of variables used in the code

int celsius1 = 0, volts1, Temp_1_F = 0;

int celsius2 = 0, volts2, Temp_2_F = 0;

float Temperature, Temp1=250, Temp2=260;

int Cook_Cycle = 1, MF=10000;

// initializing the pin numbers

int Btn_Emergency = 2;

int Probe_1 = A4;

int Probe_2 = A5;

int Heating_Element = 12;

int Alarm_HIGH = 11, Alarm_LOW = 10;

// initializing the variables for time values

int prevmls1 = 0;

int prevmls2 = 0;

int prevmls3 = 0;

int prevmls4 = 0;

int currmls;

// defining the delay values for different cook cycles

int interval_1 = 3, interval_2 = 1;

int Array_time_1[100];

int Array_time_2[100];

int Array_T_1 [100];

int Array_T_2 [100];

int i = 0;

int k = 0;

float Log_interval = 1; // Logging values at user defined interval

bool flag_low_alarm = false, Low_Flag=false;

Applications of Industrial Oven Project:

- Food Processing: Ensures uniform baking or drying across the entire oven, improving product consistency and quality.

- Material Curing: Provides even temperature distribution for curing materials like plastics or composites, enhancing the durability and quality of finished products.

- Heat Treatment: Used in metallurgy and manufacturing to ensure consistent heat treatment processes for metals, preventing defects caused by uneven heating.

This project offers a robust and reliable solution for industrial oven temperature control, combining precise monitoring with user-friendly operation. The inclusion of dual temperature sensors ensures uniform heating, while the use of LEDs for visual indications and alerts enhances operational safety and efficiency.

Benefits of Industrial Oven Project:

Precision Control: The combination of buttons and a potentiometer allows for both coarse and fine temperature adjustments, while the PID algorithm ensures stable temperature maintenance.

Visual Feedback: LEDs provide immediate visual indications of the system’s status, enhancing operational safety and making it easier for operators to monitor the process.

User-Friendly Interface: The system is designed for ease of use, with intuitive controls and clear visual indicators, minimizing the need for extensive training.

Safety Features: The error LED serves as an early warning system, helping to prevent accidents or damage due to overheating or system failures