The Powder Dispenser Machine with Touch LCD Control using Arduino Mega is an advanced, user-friendly system designed for precise and automated dispensing of powders. The system incorporates multiple sensors, stepper motors, and a touch-sensitive LCD interface to provide accurate control and a seamless user experience. The integration of sensors, motors, and a touch LCD interface with Arduino Mega provides a robust, user-friendly, and customizable system, suitable for a wide range of applications. There will be 3 Tanks which will be used as Powder source. This Powder Dispenser Machine project is a versatile and reliable solution for industries requiring precise powder dispensing. It is ideal for applications in various industries such as food processing, pharmaceuticals, and manufacturing.

Components used in Powder Dispenser Machine

- Arduino Mega:

- Acts as the central controller, managing inputs from the sensors and the touch LCD, and controlling the stepper motors for precise powder dispensing.

- Nextion Touch LCD:

- Provides an intuitive interface where users can select the powder source (Tank 1, Tank 2, or Tank 3), set the desired amount of powder, and monitor system status.

- Allows users to rename tanks, for example, “Flour” for Tank 1 or “P Powder” for Tank 2, providing clarity on the contents of each tank.

- Displays real-time data, such as powder levels, and allows for language selection, statistics viewing, and system settings adjustment.

- Stepper Motors (3 units):

- Each stepper motor controls the dispensing mechanism for a different powder tank. The precise control of the motors ensures accurate dispensing based on the user’s input.

- Ultrasonic Sensors (3 units):

- Positioned above each tank, these sensors monitor the powder levels. If a tank runs low during dispensing, the system stops, and an alert is displayed on the LCD, prompting the user to refill the tank.

- Provides visual feedback on the LCD with green indicating a full tank and red indicating an empty tank. The display can also graphically show the powder levels (e.g., half-full or full).

- Laser Sensor:

- Ensures accurate positioning and detects whether the cup or beaker is correctly placed on the scale before dispensing. The machine won’t start if the cup is absent or improperly positioned.

- Load Cell Sensor:

- Measures the weight of the powder being dispensed in real-time. The machine stops dispensing once the target weight is reached. If the cup’s capacity is exceeded, the machine alerts the user and pauses, allowing the cup to be emptied before continuing.

Working of Project:

Startup:

- On startup, the machine displays an intro logo on the touch LCD. Users are greeted with a screen showing the status of all three tanks, including their names and powder levels.

User Input:

- The user selects the desired tank (e.g., Tank 1, Tank 2, or Tank 3) and specifies the amount of powder to dispense in grams. The LCD provides options to rename tanks and set the desired weight.

Dispensing Process:

- The machine checks if the cup is correctly positioned using the laser sensor. If the cup is absent or misaligned, the machine won’t start and an alert is displayed.

- The appropriate stepper motor begins dispensing powder from the selected tank. The load sensor continuously monitors the weight of the dispensed powder.

- If the set weight is reached, the machine stops. If the cup is full before reaching the set weight, the machine pauses and prompts the user to empty the cup and press continue to finish the process.

Notifications and Alerts:

- If a tank runs empty during dispensing, the system pauses and alerts the user to refill the tank. The user can choose to refill and continue or cancel the process.

- The machine provides maintenance notifications, such as reminders to clean the tanks or other parts after a set number of operating hours.

Additional Features:

- Auto-Off: The machine has an auto-off feature after 3 hours of inactivity, configurable in the settings menu.

- Statistics Tracking: Users can access a statistics page to view total grams dispensed, hours of operation, and other usage metrics.

- System Info: An “About the Machine” section displays software version, machine ID, and other relevant information.

- Calibration Option: A service menu, accessible with a code, allows for calibration of the sensors. For instance, users can reset the scale to zero with an empty cup on it.

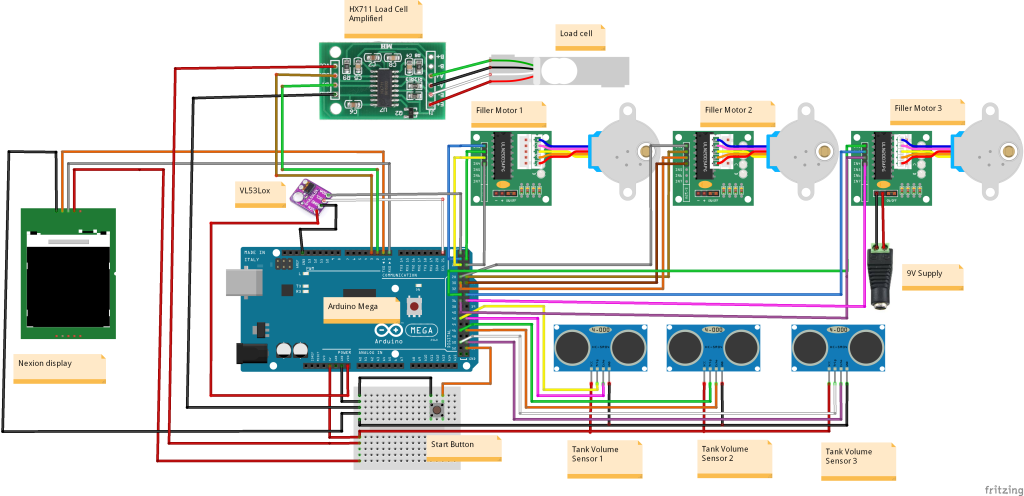

Circuit Diagram Powder Dispenser Machine Project:

Code:

#include <HX711_ADC.h>

#include <EEPROM.h>

#include <Wire.h>

#include <VL53L0X.h>

#define RX_PIN 14 // Connect this pin to the Nextion display's TX pin

#define TX_PIN 15 // Connect this pin to the Nextion display's RX pin

//-------------------------------Parameters you can edit-----------------------------

int Set_value = 1000; //This is the maximum safe volume that can be filled in the cup, you can edit it as per your conditions

float R = 6, h, container_V = 1483 ; // You can change the container volume "container_V" and radious "R" here in cm

int Target_Weight = 10; // You can change the target weight here in grams that will be initial weight appearing on the screen

int Target_Volume = 500;// You can change the target volume here in grams that will be initial volume appearing on the screen

int Weight_factor=10; //Weight increment/decrement factor on GUI

int Volume_factor=5; //Volume increment/decrement factor on GUI

//-------------------------------Load Cell parameters initializations-----------------

const int HX711_dout = 2; //mcu > HX711 dout pin

const int HX711_sck = 3; //mcu > HX711 sck pin

int prevmls = 0;

HX711_ADC LoadCell(HX711_dout, HX711_sck);

bool newDataReady = false, Sel_W = false, Sel_V = false, Tank_Filling = true, jar_Empty=true;;

long prevmls0;

float Weight;

bool f1 = false, f2 = false, f3 = false;

int Distance = 0, Percentage;

//--------------------------Ultrasonic Sensor pins initialization---------------

#define trigPin1 42

#define echoPin1 43

#define trigPin2 46

#define echoPin2 47

#define trigPin3 50

#define echoPin3 51

float dist1 = 0, dist2 = 0, dist3 = 0;

int Tank_V1, Tank_V2, Tank_V3;

//----------------------------- Define flight sensor parameters---------------

VL53L0X sensor;

#define LONG_RANGE

#define HIGH_ACCURACY

float Volume = 100;

bool Fill = false, Start =false;

//--------------------------Stepper motors pins initialization---------------

#define STEPPER1_PIN_1 22

#define STEPPER1_PIN_2 23

#define STEPPER1_PIN_3 24

#define STEPPER1_PIN_4 25

#define STEPPER2_PIN_1 28

#define STEPPER2_PIN_2 29

#define STEPPER2_PIN_3 30

#define STEPPER2_PIN_4 31

#define STEPPER3_PIN_1 34

#define STEPPER3_PIN_2 35

#define STEPPER3_PIN_3 36

#define STEPPER3_PIN_4 37

int step_number1 = 0, step_number2 = 0, step_number3 = 0;

void setup()

{

Serial.begin(9600);

pinMode(53,INPUT_PULLUP);

Stepper_Pin_Declaration();

Load_Cell_Initialize();

}

Benefits of our Powder Dispenser Machine Project:

Precision and Accuracy: The combination of stepper motors and sensors ensures accurate and consistent powder dispensing.User-Friendly Interface: The Nextion touch LCD offers a clear and intuitive interface, making the system easy to operate with minimal training.Safety and Error Handling: Built-in sensors prevent operation without a correctly positioned cup and pause the system if the cup is full or a tank is empty.Customizability: Users can rename tanks, set dispensing amounts, and configure various settings according to their needs.Maintenance and Monitoring: The system provides timely notifications for maintenance and allows users to track usage statistics for better management.

Applications of Powder Dispenser Machine Project:

The Powder Dispenser Machine with Touch LCD Control using Arduino Mega is a versatile and precise system that can be applied in various industries. Its ability to accurately dispense powdered materials makes it suitable for numerous applications, enhancing efficiency, reducing waste, and improving product quality. Here’s a detailed look at the potential applications of this project:

1. Pharmaceutical Industry

Medication Preparation

- Precise Dosing: In pharmaceutical manufacturing, precise dosing of powdered ingredients is critical for ensuring the efficacy and safety of medications. The powder dispenser can accurately measure and dispense active pharmaceutical ingredients (APIs) and excipients, minimizing the risk of dosage errors.

- Custom Medication Compounding: Pharmacies that prepare custom medications can use the dispenser to accurately mix and dispense specific powder formulations based on individual patient needs. The system’s ability to store and recall different recipes enhances workflow efficiency.

Capsule Filling

- Automated Capsule Filling: The machine can be integrated into an automated capsule filling process, where precise amounts of powder are dispensed into capsules. This is particularly useful in producing consistent dosage forms in large volumes.

2. Food and Beverage Industry

Baking and Cooking

- Ingredient Dispensing: In bakeries and food processing plants, the dispenser can be used to accurately measure and dispense dry ingredients such as flour, sugar, cocoa powder, spices, and baking powders. This ensures consistency in product quality and reduces the likelihood of human error during ingredient mixing.

- Customized Spice Blends: Restaurants and food manufacturers that produce custom spice blends can use the machine to create precise mixtures, ensuring that each batch meets the same flavor profile.

Nutraceuticals and Dietary Supplements

- Powdered Supplements: The dispenser is ideal for measuring and packaging powdered dietary supplements, such as protein powders, vitamin blends, and herbal extracts. The system’s accuracy ensures that each package contains the correct dosage, which is crucial for product effectiveness and regulatory compliance.

3. Cosmetic Industry

Cosmetic Powder Formulation

- Manufacturing of Powders: In the cosmetic industry, products like face powders, eyeshadows, and blushes require precise formulation to ensure uniform color, texture, and performance. The powder dispenser can be used to measure ingredients with high precision, leading to consistent product quality across batches.

- Customized Blends: The machine can also be used in custom cosmetic formulation labs where bespoke powder blends are created based on customer preferences.

4. Chemical and Materials Processing

Powder Blending

- Chemical Mixture Preparation: In chemical manufacturing, accurate mixing of powdered chemicals is often required to create specific compounds or materials. The dispenser ensures that the correct ratios of each powder are used, which is critical for chemical reactions and product consistency.

- Materials Science: For the preparation of advanced materials, such as ceramics, composites, or powdered metals, the dispenser can precisely measure and combine powders, ensuring uniform material properties.

5. Laboratory Research

Experimental Formulation

- Precision in Research: Research labs often require precise measurements of powdered substances for experimental formulations and testing. The powder dispenser can help researchers accurately prepare samples, reducing variability in experimental results.

- Custom Experiments: Researchers can use the machine to automate the preparation of different powder mixtures, saving time and improving reproducibility in experimental setups.

6. Agriculture and Horticulture

Fertilizer and Soil Additives

- Controlled Dispensing of Fertilizers: In agricultural applications, the dispenser can be used to measure and dispense powdered fertilizers, soil amendments, or pesticides. Accurate dispensing ensures that the right amount of product is applied, promoting healthy plant growth while minimizing waste.

- Customized Soil Blends: Horticulturists can use the machine to create custom soil blends by precisely measuring and mixing different types of soil amendments, ensuring optimal conditions for specific plant species.

7. 3D Printing and Additive Manufacturing

Powder-Based 3D Printing

- Material Handling: In additive manufacturing, especially in powder-based 3D printing processes like Selective Laser Sintering (SLS), the powder dispenser can be used to precisely measure and feed powdered materials into the printer. Accurate material handling is essential for the quality and consistency of printed parts.

8. Education and Training

Teaching Tool

- Educational Demonstrations: The powder dispenser machine can be used as a teaching tool in educational institutions to demonstrate principles of automation, sensor integration, and precise control in manufacturing processes. Students can learn about the applications of mechatronics in real-world scenarios.

- Research and Development Projects: Educational labs can use the dispenser for student projects involving precise measurement and control, allowing students to develop hands-on experience with industry-relevant technologies.

9. Medical and Healthcare

Medical Device Manufacturing

- Precise Material Dispensing: In the manufacturing of medical devices that require powdered materials, such as drug delivery systems or biocompatible coatings, the dispenser ensures that each device receives the correct amount of material, maintaining product quality and safety standards.

10. Home and Small Business Use

DIY and Craft Projects

- Custom Blends: Hobbyists and small business owners can use the powder dispenser for creating custom blends of powders, whether for craft projects, DIY cosmetics, or small-scale food production. The machine’s accuracy ensures professional-quality results.

Conclusion:

The Powder Dispenser Machine with Touch LCD Control using Arduino Mega is a powerful tool that can be tailored to various industries requiring precise powder dispensing. Its applications range from pharmaceutical manufacturing and food processing to laboratory research and agricultural use. The system’s accuracy, customizability, and user-friendly interface make it an invaluable asset in settings where consistency, efficiency, and precision are paramount. Whether used in large-scale industrial operations or small-scale artisan production, this machine offers significant improvements in process control, product quality, and operational efficiency.